We’ve talked about using stainless steel as the main material in tank fabrication, but we also utilize metal alloys in fabrication. Alloys are the result of modifying different materials to create the best physical and chemical property for fabrication. Today’s Tank Talk will take the opportunity to walk through some of the best aspects of alloys and explain why they are utilized in tank fabrication.

Alloys have altered melting points. In several industrial processes, the melting point of each material being used is significant. Boilers and other commercial tanks have to be built with materials with a higher melting point. Conversely, manufacturers might need an alloy material with a lower melting point because it is easy to fuse. Being able to adjust melting points using different alloys makes custom fabrication easier and more efficient.

Alloys can be physically harder. Naturally occurring metals are actually very soft and not fit for industrial use. When metal materials are combined to form alloys, a hard material can be created. This is especially beneficial in tanks that are storage, pressure, or reactor vessels because tanks fabricated with the harder alloys can easily withstand the conditions of the intense operational environment of these industrial tanks.

Alloys are more resistant to corrosion. Wear and tear occurs naturally over time, and many industrial losses can be linked to corrosion. This is why alloys are utilized; alloy materials can be created to offer maximum corrosion resistance. This happens when non-metal materials are added to metals to create resistant alloy materials, which will extend the life of a fabricated tank.

Alloy formation can be increase tensile strength. Some alloys have incredibly high tensile strength, especially for industrial tanks involved in extreme pressure conditions.

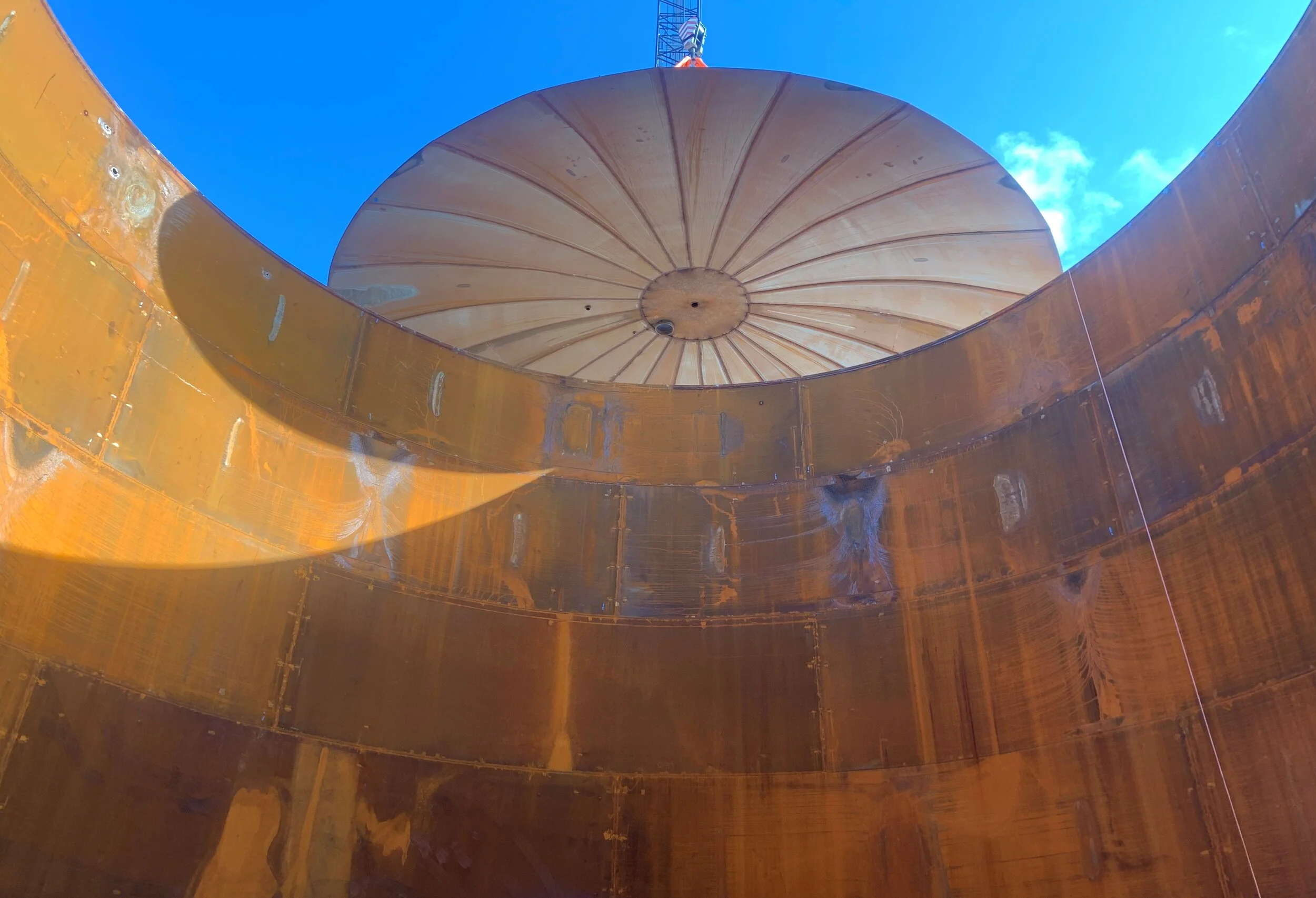

Chattanooga Boiler and Tank is proud to be an expert in the tank fabrication. Our team manufactures tanks and vessels of stainless steel, carbon steel, duplex stainless steel, nickel alloy, aluminum alloy, hastelloy, inconel and other exotic materials. If you are curious about how alloys can be utilized for your company’s tank fabrication, please contact us!